CUSTOMER:-- WASTEWATER MANAGEMENT & TREATING PLANT A Manager of Wastewater treatment facility had Difficulties with accuracy output of thickened sludge custody transfer flow measurement. The Plant produces thickened slurry which is temporarily collected in holding tanks. The slurry were loaded in to pulling trucks to be transferred to landfills and other users. This plant was previously running with a clamp-on ultrasonic flowmeter in an 10-Inch. Pipe for custody transfer flow measurement. The Flowmeter inaccurately measured the comprised flow of the thickened slurry hauled due to coating and the high solids particles. Imprecise output of custody transfer measurement provoked in several negative business impacts. The treatment facility frequently over paid the hauling company based on the inaccurate measurement. High costs of operation resulted from excess hauling truck trips due to under filled trucks. Repeated maintenance works of the ultrasonic meter and flushing/cleaning the lines to remove clusters/build- up also resulted in high cost of maintenance.

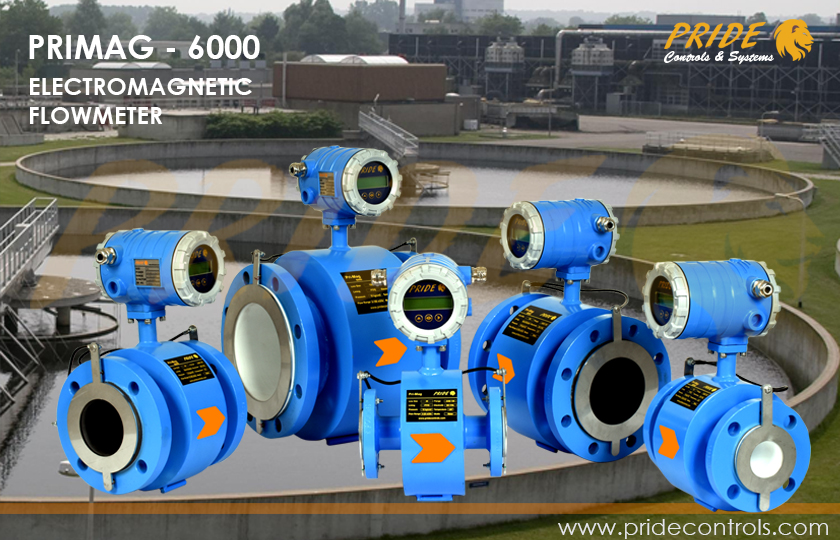

Solution:-- Found the existing flowmeter not suitable due to high solid slurry content after evaluation of their usage we suggested Electro Magnetic Flowmeter System solved the Plant Manager’s problem of inaccurate sludge measurement. The Electromagnetic flowmeter provided higher flow accuracy and was not affected by the high solid content slurry. Decreasing the EM flowmeter size below the line size scale up the velocity into the meter and reduced the build-up

Keywords

ultrasonic flowmeter

high solids particles

WASTEWATER MANAGEMENT

inaccurate measurement

high solid content slurry

high solid slurry content

Electromagnetic flowmeter

custody transfer measurement

inaccurate sludge measurement

Wastewater treatment facility

excess hauling truck trips due

Electro Magnetic Flowmeter System

several negative business impacts

sludge custody transfer flow measurement